Fooditor: The Farmer, The Airport Sandwich, and the Future of Food

by Michael Gebert | December 14, 2018

Behind a Rick Bayless sandwich at the airport, there’s the story of a family farmer reinventing farming

YOU ARE BEING HERDED UP one way and down the other. Shuffling along in a slow procession until you reach the inspector, who looks you over and with his stamp, sends you through. Then it’s down a metal and glass hall to a gate, where you stumble down a chute and into a metal tube, to be disconnected from this earth entirely until you arrive at your final destination.

You’ve done all this at O’Hare countless times, even though none of it would be recognizable to your ancestors of just a few generations ago, simple farming folk. None of it, that is, except for one thing. You stop at a stand called Tortas Frontera, from Chicago chef Rick Bayless, and after surveying your choices, you order a Torta Cubana, a dressed-up take on a Cuban sandwich. Like everything at the airport, maybe a little pricey, but what are you gonna do. Waiting for the buzzer in your hand to go off, you read a board which tells you about the farmers who supplied some of the ingredients here.

The pork here is said to come from a farmer named Greg Gunthorp, in Indiana. You, you’re going from one metal tube to the next today, flying miles up in the air. It’s the most unnatural thing imaginable. But the one thing that makes you feel a little grounded on this earth today is the food you eat, and with it, the picture you get—that somewhere, somebody named Greg Gunthorp is working the soil and feeding his animals today, in the traditional ways, so that you can enjoy a natural lunch.

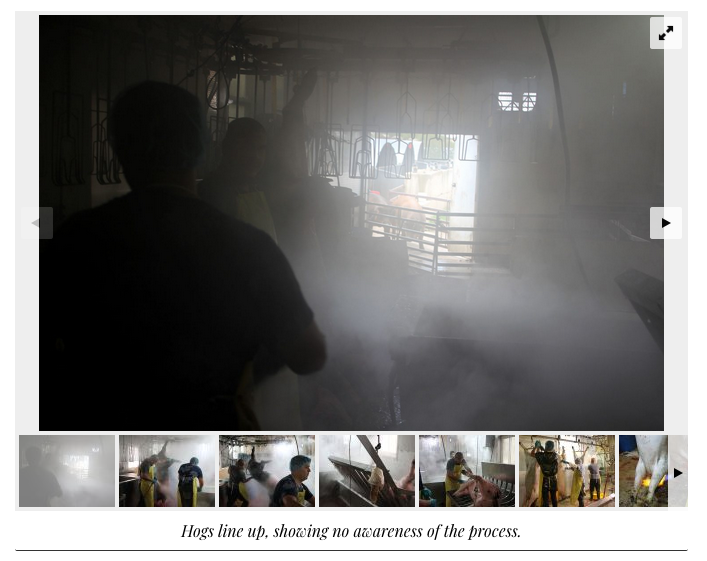

I AM IN THE PROCESSING PLANT on Greg Gunthorp’s Indiana farm, three hours from Chicago, a little north of Fort Wayne. Specifically, I’m in the slaughter room, a Renaissance painting of a room, stark tableaux of billowing steam and blood on the concrete floor. There is an ominous energy in the air, like the aftermath of a lightning strike; a sense of the potential for violence just in the fact that two men are dealing with a creature almost exactly as big as they are, and efficiently and unemotionally taking its life. It’s the part no one likes to dwell on, but without it there is no meat, and no meat farmers, and I’m starting my visit by confronting it directly. I have to remember to keep snapping photos, because my instinct is to stop and observe the moment. To pay respect.

When I’m done I step back out, from steam into summer air, and I go across the hall. Here, one of Gunthorp’s workers is operating a slicer with a conveyor belt. He takes a smoked pork loin, brown and gnarled like a log, from a white bucket and feeds it into the machine. The blade whirs and pink smoked slices come out the other end, which he stacks in plastic bins. From there, they will go straight to O’Hare, to be put on the Torta Cubanas at the Tortas Frontera locations in Terminals 1, 3 and 5.

We talk about the food chain, but as often as I’ve been to farms and restaurants, I’ve never seen it so literal and so compacted. It’s perhaps 15 feet from the live hogs on one side of the hall to the portion-controlled sandwich slices on the other. Even all the other steps in between take place within this one building—the carcasses are chilled, cut up, and smoked, all just down the hall. The hogs themselves are raised within walking distance, somewhere on the 270 acres of this farm.

In short, it’s a system designed so that pigs travel as little as possible—so that you can travel all over the world with Gunthorp pork on a Bayless torta in your belly.

At first glance, Greg Gunthorp lives the idealized life of the American family farmer, working with his family on his own land. What makes that possible for him, though, has less to do with preserving the tradition ways of farming than it does with radically rethinking them. Greg Gunthorp has figured out how to enable them to function as a cog in a ruthless industrial system, while maintaining for himself the things about farming that matter to him—better meat, more humane practices, building something that his children can carry on after him.

Frankly, everything about that is next to impossible on American farms today, a world where farmers take side jobs at Wal-Mart because prices have been pushed down so low at places like… Wal-Mart. If family farms have a future, if our food system is going to be healthier and more sustainable, how that happens is going to look a lot like Greg Gunthorp’s farm—and the pork on an airport sandwich.

“WE RAISE HERITAGE BREEDS of pigs—so Durocs, Duroc cross-breeds, raised on pasture, raised without antibiotics,” Greg Gunthorp says. “They’re outside their whole life, raised in the traditional, family-scale agriculture, before the industry consolidated—and all the hogs went inside.”

Standing next to his processing building, his home looking out on his land in the distance, Gunthorp looks the part of a midwestern farmer, muscular but a little well-padded with his own good food, easy in manner and easy to smile, his speech rolling out with a country drawl. Rick Bayless tells me, “He comes off as a good old boy, and maybe not the brightest guy—well, that’s all a sham,” he laughs. “Because the guy is super brilliant. He reads, he writes—I had the opportunity to hear him speak the other day. He spoke for half an hour without a single note in front of him, he’s an amazing speaker.”

Gunthorp’s family’s been raising pigs in Indiana for four generations; his grandparents bought this land in about 1955 “when the toll road came through,” an historical event of almost Biblical stature, it seems. His goal was to keep doing what they had done—but he quickly realized that “I was getting less per hog than my grandfather was—in the Depression.”

Let me pause for a second to explain the commodities markets, like Randolph Duke does for Billie Ray Valentine in Trading Places. Commodity markets standardized farming to work like any other industrial good—if you meet the standard for an item, you can sell it into the system and get the going price. But that’s not good for people who deviate from the standard—like by raising heritage breeds because they taste better. There’s no easy way to reward “tastes better” in a commodity system.

And the markets force prices down to rock bottom, so that in order to make money at raising pigs, farmers are basically forced to adopt certain breeds, and one highly industrialized way of raising them—the CAFO (confined animal feeding operation) system where pig production is concentrated indoors. To not do so is to eliminate your chance of squeezing out any profit in the existing system. Your only hope then is to find someone willing to pay for what you do differently.

“Raising pigs on pasture, breeds of pigs that are too fat and so on—there’s not a commodity market for those hogs,” he says. “But there is a customer base for them, and I want to raise them because I’m a pig farmer. So in order to do that, we have to have a processing plant.”

I ask him why he can’t just use the small rural processors used by farmers who mainly sell to the farmers markets. “Those guys are good butchers, but they’re not the kind of places that cut for Rick Bayless and Charlie Trotter,” he says. “If you’re going to sell to upscale restaurants, fine dining restaurants, the product has to be able to be butchered and portioned for them. I didn’t think we’d be able to do what we do without owning the processing plant.”

So in the late 1990s he went in with some other farmers on a plant, which each of them would use one day a week. Bad idea. “It actually failed pretty miserably,” he says. “The other three partners who were ostrich farmers, they shared the losses with us. But I was stubborn enough that I said, we can make this work if we build a processing plant here on the farm.”

He quickly discovered something else that the industrialization of agriculture had done to American farming: created a bias toward big food production at the U.S. Department of Agriculture. He started his plant under a state license, but he needed federal certification to sell to the big restaurant market west of Indiana.

“It took 14 months after we filled out the Grant of Inspection with the USDA district office in Chicago till they’d even come out and visit with us,” he says. “So you have to be pretty stubborn to be a little plant and deal with the USDA.”

That experience is, perhaps, what gave Gunthorp a second career as an activist on behalf of small family farms, campaigning in Washington and speaking at conferences all over the country. “I’ve seen a lot of changes, because the world’s idea of food safety in 1998, when we started, was different than it is now,” he says. “It’s getting stricter every time you turn around, but the flip side of it is, in ways it’s gotten easier for people now who want to get into the business. Back then the USDA wanted absolutely nothing to do with us. Nowadays they’re very responsive to prospective little plants. We have stakeholder meetings four times a year with the USDA, that I was instrumental in helping get started.”

“We kill their budget,” he says. “We had two inspectors today. A USDA veterinarian gets staffed to every single slaughter plant, no matter how little they are. They have a new one up across the state line, they do 8000 pigs a day, they have one veterinarian. We do 50-some pigs today. We don’t have to have a full time veterinarian, but they have to have one available for our plant. We have to have a whole line inspector for the full eight hours on the day we slaughter. It costs them a lot of money.”

I saw the cramped office allotted to the on-site inspector. “We don’t do anything near as close to exactly the same [day after day] as the big guys. They got fancy offices for ‘em, and automated lines, and they go out and look and it’s the same as the last time, and it’s the same as the last plant they were at,” Gunthorp says. “People have to make decisions when they come to a little plant.”

Surveying his lands before him, he gives an ironic laugh. “If I had any business on the planet to pick to be in, from an economic standpoint, from a headache standpoint, owning a USDA slaughter plant would probably be one of the last on my list.”

FOR SOMEONE WHO WAS BETTING his way of life on a new class of customers in chefs, Gunthorp didn’t really know much about the restaurant scene when he first started trying to sell in Chicago. Around 1998 another farmer he knew was selling eggs to a few restaurants, and at first Gunthorp followed his lead.

“I didn’t have any idea who Charlie Trotter was,” Gunthorp says. “I just called them up, and I wound up talking to [chef de cuisine] Matthias Merges for 15 or 20 minutes. He was very knowledgeable about pork quality, which was unusual then.”

He started selling pigs to Trotter, and that led to other connections. He sold to Ted Cizma, who had a restaurant named Grace (preceding the Curtis Duffy one); Cizma introduced him to his next door neighbor on Randolph, Paul Kahan at Blackbird, and Kahan urged him to talk to Rick Bayless.

Bayless recalls, “He came with this guy who was selling eggs, and rabbits, and a few other things. And he wanted to sell us pigs, but we already had a pig farmer, it was this guy up in Wisconsin. And he was doing fine, but he wasn’t offering the same product that Greg did. We’re very loyal to our suppliers, so we didn’t really do anything with this other guy’s pork, but we kept seeing Greg come around with the guy with the eggs. And I said to him at one point, do you ever do chickens? And he said no, I haven’t done any chickens except for my own family’s use.”

Well, could you? It took three years to ramp up to that level, Bayless says, but by the end of it Frontera and Topolobampo had switched entirely over to the thing that is now his best-known brand name on Chicago menus—Gunthorp chickens.

“Because he was going to do fully free-range chicken, it was a big learning curve on his part and on our part, how to sell it,” Bayless says. “If you compared the flavor of the old chicken to his chicken, basically you noticed that his had a whole lot of flavor and the other one doesn’t have a whole lot of flavor. We had guests coming in and saying, ‘What did you do to your chicken? It tastes spoiled.’ Because I was giving them full-flavored chicken.

“We had to go back and forth with it and figure out how to brine it and all that sort of stuff. And it was a labor of love. My wife said, on more than one occasion, when are we going to stop this? Because we’re getting too many negative responses from our guests. And I said, we’re gonna figure it out, we’re gonna figure it out. Let’s just keep building this project.”

Project is the right word, especially once Bayless’ previous pork supplier retired a few years later and they switched over to Gunthorp’s pork as well. Gunthorp poured everything he had into increasing his pork production.

“At one point he had bought more equipment than he could support, and he knew the bank was going to foreclose on him,” Bayless says. “It could have spelled the end of his farm. We were his biggest customer, and he came to talk to our controller and said, ‘You guys are going to buy this amount of chicken and this amount of pork from me over the next three months. Is there any way that I could just borrow all that money?’ Our controller lent him the three months and we kept him going, and I didn’t even know that had happened until years later, when we were at a conference and he told the story.”

Restaurants are the original assembly line, in one sense, but restaurants like Rick Bayless’s also put themselves forward as artisanal workplaces, and it’s true in that they can take a whole animal from a farmer and break it down into parts in house. Supplying a business like an airport fast food stand is very different. There isn’t the room, the skilled workforce, or the quiet time before service to do things like that—it’s knocking out orders 18 hours a day. If he was going to supply Tortas Frontera, Gunthorp would need to furnish them product ready to go straight on a sandwich—the business of a factory more than a farmer, and of a chain more than a chef-driven restaurant.

When I ask Bayless if he had specific specs for the pork for the Cubana, he kind of scoffs—a smoked pork loin is a smoked pork loin, you know? “Greg had built a smokehouse, and—he’s not a cook, and when you’re moving into smoked products, you’re moving into my territory,” Bayless, whose parents owned a barbecue restaurant in Oklahoma, says. “He talked to some of the people he supplies pork for who do curing and smoking, what percent brine do you work with, how long do you smoke it at what temperature. So he did some tests for us, and we decided on the one that we liked.”

Being able to deliver that product required, again, a daunting leap into the financial unknown—from farming to manufacturing on his land. The slicing equipment cost tens of thousands of dollars, and the one I took pictures of here has since been replaced by a faster, even more expensive one. It was time for me to leave the factory part of his farm, and see why it was worth it.

WE’RE DRIVING AT WHAT FEELS to me like a 45-degree angle up a hill, in a battered farm vehicle; I have one hand on my audio recorder, and the other on a bar to keep from falling out. Just the terrain alone is unusual for a farm; Gunthorp says it’s what’s classified as “recreational,” as in snowmobiles, I presume, and thus less expensive acreage than efficient, flat-as-a-board farmland.

But Gunthorp didn’t want the land to build a CAFO. At each level, sections of the hill are squared off with fences, and behind them, a group of mothers and their suckling pigs run around together in the open, doing adorable pig things. They have a corrugated metal shelter, and food and water, but otherwise they are free to roam and root around within their area as they would have a thousand years ago. This is what free-range looks like when it’s not just marketing words on a package.

“I dont know if you’ve ever been in the [CAFO] buildings, but in my opinion, the pigs don’t look like the same animals. They’re clinically depressed,” he says. “These guys get to move the muscles, which is what we’re consuming, they get to actually root around.”

He says, “I personally believe that we have a moral obligation to let pigs be pigs. We don’t need to attach human rights to pigs, but we should attach pig rights to pigs. We have an obligation—food, water, bedding, shelter, a fence for protection. But we also have an obligation to let them do this.”

They certainly look happy. Unbeknownst to the pigs, however, there is a system. There are 50 paddocks marked off, each for a certain age. “It’s so much simpler for our employees to understand,” Gunthorp says. “We put the gilts that haven’t farrowed down there, we put the sows that haven’t farrowed in the next row over. And then you just start the clock. The ones that haven’t farrowed, one week later, just go right next door to the next pen in a lane. They move over there easily.”

So this isn’t hippie farming in the open—it’s free range, traditional farming, organized to work like a machine. “In lots of ways we’ve moved more to the approach that the big guys use just because it’s easier for the employees,” Gunthorp says. “And I think that’s what’s really going to scare the big guys, because when you start to introduce some efficiency, and some lean manufacturing and some process control behind this whole thing, and you interject the science into it, and you got the consumers saying hey, this is what we really want, and there are a few guys in the country who are doing it at scales that start to become big numbers by the end of the year—then, maybe we could really change the world.”

Rick Bayless sees Gunthorp’s well-regulated systems as having another benefit, for humans as well as animals. That’s his division of labor—slaughter only happens one or two days a week, and the rest of the time the same workers work in other areas of the farm.

“There’s one part in The Omnivore’s Dilemma about slaughtering chickens, and Michael Pollan says if you do it every day, you just become numb to it. And then you start doing weird stuff. So how Greg operates is, he won’t let anybody slaughter animals day after day,” Bayless explains.

“The same people that feed and care for those animals are the ones that slaughter them. Which means they’re much much much more careful with them, and more reverential with the animals. They do it with, I don’t know, more empathy. I find it really remarkable that the same guy, José, who delivers the pork to us on Thursdays raises the animals, and slaughters the animals.”

Gallery: From Hog to Cubana Torta In One Place

Every step before smoked pork loin goes on your airport sandwich takes place on Greg Gunthorp’s farm, much of it within a single building. Here’s how it happens. Warning: though there is no intent to be gruesome, some may find the facts of meat processing disturbing.

SO THE SPECIAL SAUCE ON THE PORK LOIN on your airport sandwich turns out to be changing the food system and the world. It works so far as your sandwich is concerned—you buy the sandwich, Tortas Frontera buys the pre-portioned meat, doing his own processing allows Gunthorp to meet that demand while keeping his farm and his way of life what he wants it to be. That’s his food chain, and it works for him.

He goes back and forth during my visit on whether he thinks it will ever really spread enough to affect our massive industrial food system. In front of the pigs he saw the path to everyone raising food his way clearly. As we drive back, he acknowledges that getting up to scale would be an enormous investment that he, having bet the farm enough times already, isn’t able to make.

And that customers aren’t always willing to make—on a $12 sandwich over an $8 one, to pay for this level of naturally-raised, superior meat. “It’s become trendy and mainstream for people to talk about it. I don’t think it’s become trendy and mainstream for people below that elite group to actually use it,” he says.

“I used to be naive enough to believe that we were going to that level. But it’s not happening for me. Maybe for my kids some day, but I doubt it. We produce a lot of food, but we don’t make a dent in the food supply. I think it’s going to take branded groups of farmers, and it’s going to take consumers that actually get the big guys to say hey, we gotta do something different because we’re not going to have any customers otherwise.”

He sounds glum at that moment, but in all, it’s enough for now to be a model for the world. A man who didn’t believe in the future wouldn’t have invested in his latest project, a ham barn for curing prosciutto for two or three years. (Knowing the traditions of Italian and Spanish ham-making, he says, only partly in jest I suspect, “In three or four centuries, my family’ll probably be really good at making hams.”)

One thing that encourages him, at least, is that his kids are starting to be old enough now to have made the choice to return to the farm, after college (his oldest two both graduated from Purdue). “That’s probably the most exciting thing on the farm,” he says. “My son Evan manages the processing plant. My oldest daughter, Kara, she manages our sales and marketing. They work full time on the farm.”

I ask him if he thinks this style of farming encourages the next generation to stick with the family farm. “I think it’s massively more encouraging,” he says. “The big challenge for anyone who wants to farm is to figure out a way to have another income for that next generation. The typical corn and soybean farm, they tell you now, is up to 1500 acres per income generating unit. So if you want to bring your kids back to a corn and soybean farm, the land grant universities will tell you you need 3000 acres. And here, on 270 acres, we employ our family, my two oldest full time, twenty full-time employees, ten part-time employees. I don’t think figuring out an income for the next generation is a problem there.”

Still, it’s not just an economic choice. Rick Bayless tells me another story, about when he and his wife used to have a pig roast for all their employees at their Logan Square home (the staff eventually got too big for the space).

“He would meet us at our house at midnight the night before, and then he would get his pig started in our garage, he had a trailer roaster,” Bayless says. “And then he would sleep in a sleeping bag, next to the pig, with one of his kids. We would say, come in, we have a guest room, and he would be, no, I don’t want to be away from the pig in case anything happens. Then he’d get up the next morning and take his kid out to brunch some place, and then come back, and we’d have our party. And he’d carve up this pig.”

“The guy is just so incredibly dedicated to his vision. I don’t have enough words to describe what a special spirit that guy is.”

That’s what’s on your airport sandwich.